Our Services

Our Services

The Calder Metal Spinning Company has considerable metal working experience and knowledge, combined with our highly skilled work force and cutting edge CNC spinning lathes, enable us to provide you and your project with the many benefits.

Hand Metal Spinning

We operate a range of metal spinning methods including hand metal spinning, hydraulic metal spinning, shear forming and flow forming. Our wide range of existing tooling enables us in many cases to keep tooling costs to a minimum. We can in some cases modify, clean or rectify the existing tooling to suit new requirements.

CNC Metal Spinning

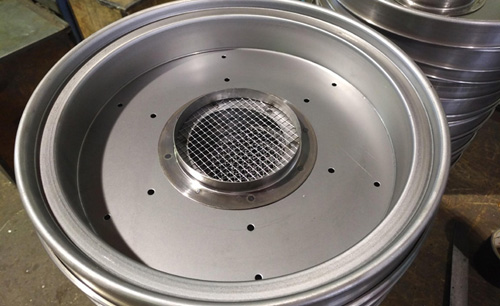

Our state of the art CNC machines allow us to mass produce high quality metal work items whilst guaranteeing superb component finishes. You can be assured the accuracy of your components will not be compromised. Every product will be dimensionally constant due to exact computer controlled cycles.

Metal Presswork

The combination of our precision CNC punch presses, and a wealth of standard CNC punch tools enable us to punch out numerous sheet metal fabrication designs without the requirement for any new tooling. As well as all standard shapes such as circles and rectangles we also offer CNC punching of specialised shapes.

Metal Fabrication

From the most simple of fabrications up to highly complex structures, we have the ability to assembled and produced these components in our factory. Utilising laser cutting and both MIG or TIG welders our factory can be producing anything from a single custom prototype up to a full series production run.

Welding Solutions

We perform aluminium, steel, copper, brass and stainless steel welding for our customers which include stainless steel pressure and containment vessels, bespoke catering installations, medical equipment, domestic heating and ventilation systems and can accommodate a wide range of welding solutions.

Bespoke Designs

We are highly proficient in producing prototype components with much experience dating back during war time to sample the British army for one-offs where needed. We regularly produce these small batch component runs for all sectors of industry where components need to be proved out before going into full production.